On January 4th, the prestigious international journal Nature published a research paper titled "Negative mixing enthalpy solid solutions deliver high strength and ductility", authored by Professor Han Xiaodong's team from Beijing University of Technology (BJUT). This represents BJUT's debut as the primary contributing institution for a paper published in Nature, marking a significant research breakthrough in the design of alloys with high strength and ductility, as well increasing understanding of the atomic-scale strengthening-toughening mechanism. Assistant Researcher An Zibing served as the first author, with Professor Han Xiaodong and Research Fellow Mao Shengcheng as co-authors. The original paper is available at: https://doi.org/10.1038/s41586-023-06894-9.

Metal materials which have exceptional strength and ductility are essential for advancing the functionality and safety of devices and equipment. However, the properties of strength and ductility in such materials tend to be mutually antagonistic, as increasing strength frequently leads to a reduction in ductility. Researchers have continuously striven to develop metallic structural materials that exhibit both high strength and high ductility. Using body-centered cubic refractory multi-principal element alloys (MPEAs) as an example, developing effective alloy design criteria and creating alloys which have both high strength and excellent tensile ductility is still a major scientific challenge globally.

Focusing on the above-mentioned scientific issues, the team, together with CAE Member Zhang Ze and other collaborators, proposed the concept of "negative mixing enthalpy solid solution" (referred to as "negative enthalpy solid solution") to design alloys with high strength and toughness. Employing this design concept, the authors incorporated the element aluminium into the near ideal high-entropy HfNbTiV alloy, resulting in a negative mixing enthalpy Al-M (M= Hf, Nb, Ti, V) multilevel heterostructures. They successfully synthesized the HfNbTiVAl10 large negative enthalpy solid solution alloy. This alloy has exceptionally high yield strength and superb tensile ductility, solving the long-lasting challenge of the strength-ductility trade-off in refractory MPEAs. The design concept is extensive in its generality and applicability, and has been validated with various body-centered cubic and face-centered cubic multi-component alloys. This breakthrough research efficiently guides the chemical composition design of high-strength and ductile multi-component alloys with different structures, thereby advancing the development of alloys with high strength and toughness. It introduces a fresh perspective for addressing the prolonged strength-ductility trade-off challenge in the field of metallic materials.

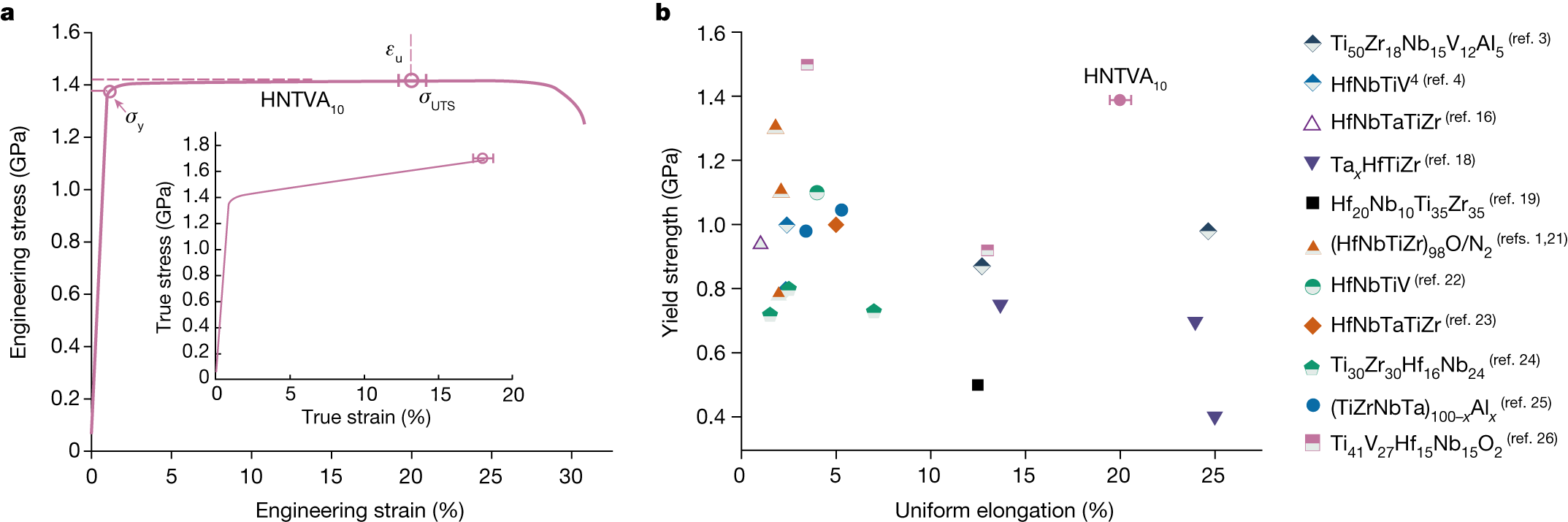

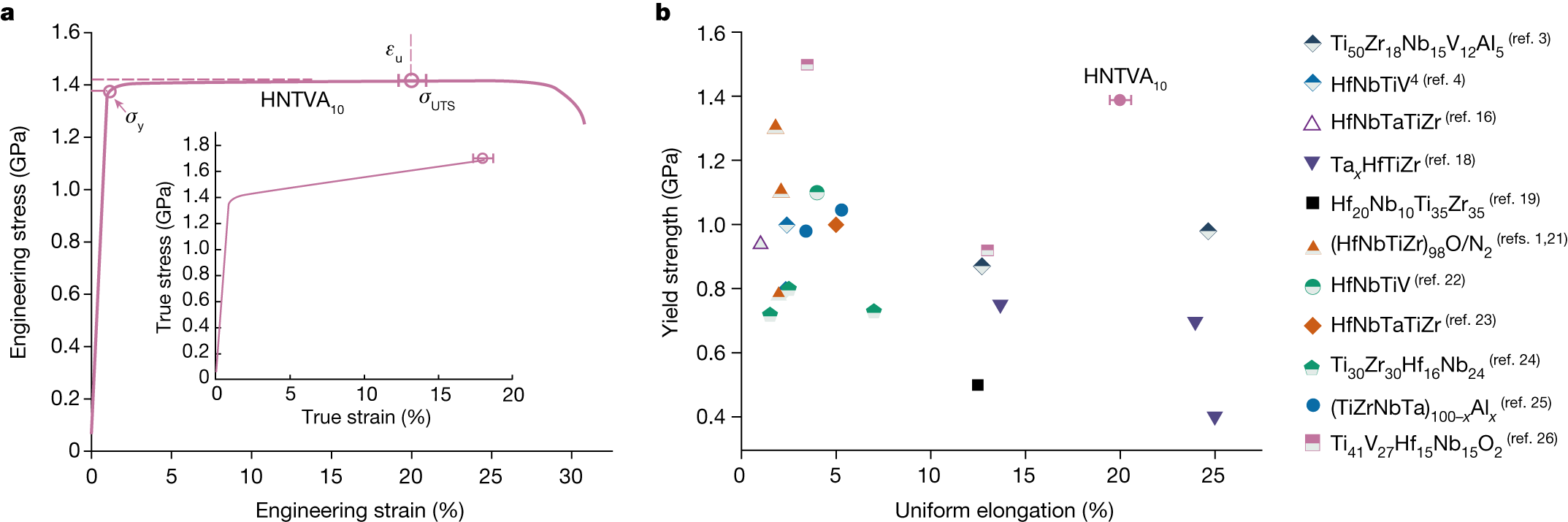

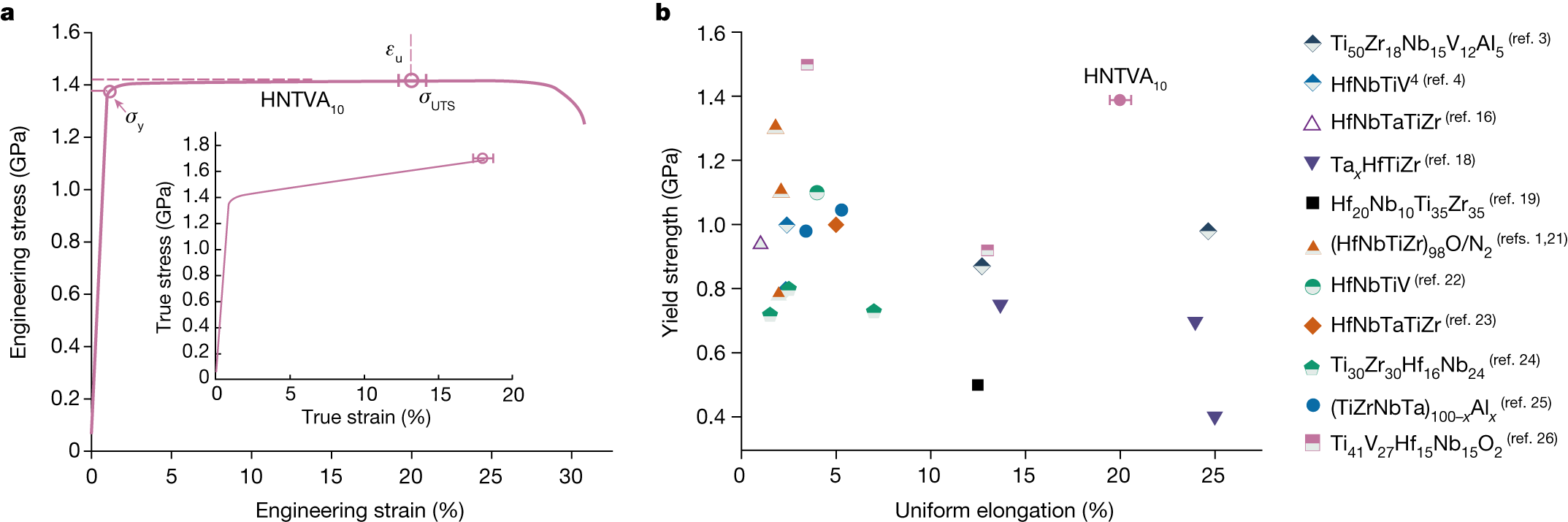

(Figure 1: Tensile Strain-Stress Curve. The HfNbTiVAl10 alloy exhibits outstanding yield strength and uniform tensile ductility, its comprehensive properties exceeding the mechanical performance of similar refractory MPEAs.)

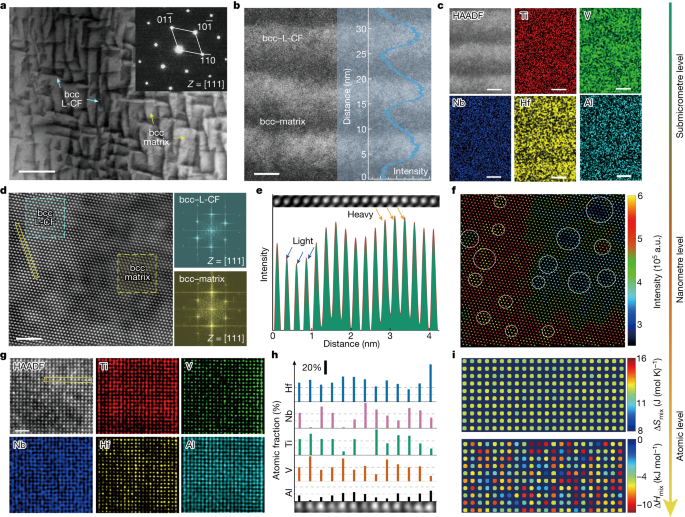

(Figure 2: The negative enthalpy-induced multi-scale chemical composition fluctuation structural forms within the HfNbTiVAl10 alloy.)

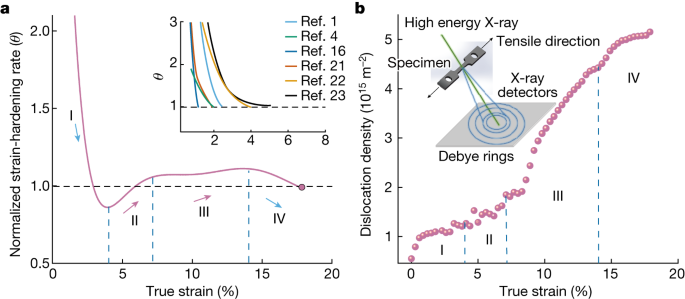

(Figure 3: In-situ synchrotron tensile experiments which reveal the evolution pattern of dislocation density with increasing strain, ensuring a high normalized strain-hardening rate of the alloy over a wide strain range.)

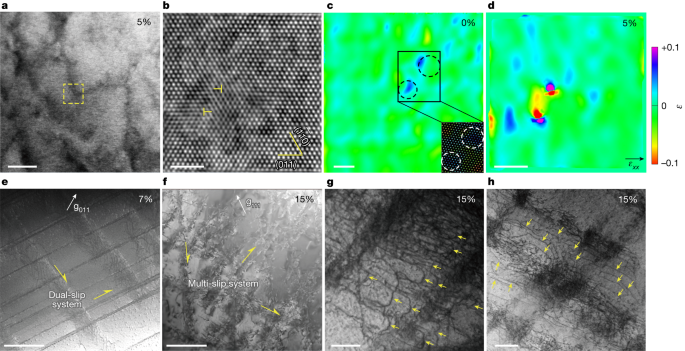

(Figure 4: The multi-scale chemical composition fluctuation structure promotes the multiple slipping and cross slipping of dislocations, facilitating dislocation accumulation.)

Based on comprehensive experimental results, theoretical calculations, and literature reviews, it has been established that a linear relationship exists between alloy yield strength and mixing enthalpy, leading to the mechanism of negative mixing enthalpy strengthening being proposed for the first time. As a result, the negative enthalpy solid solution approach not only improves alloy strength, but also induces the formation of multi-scale chemical composition fluctuations which improve ductility. This new strategy reconciles the conflicting relationship between material strength and ductility, presenting a fresh approach to the design of alloys with high strength and toughness.