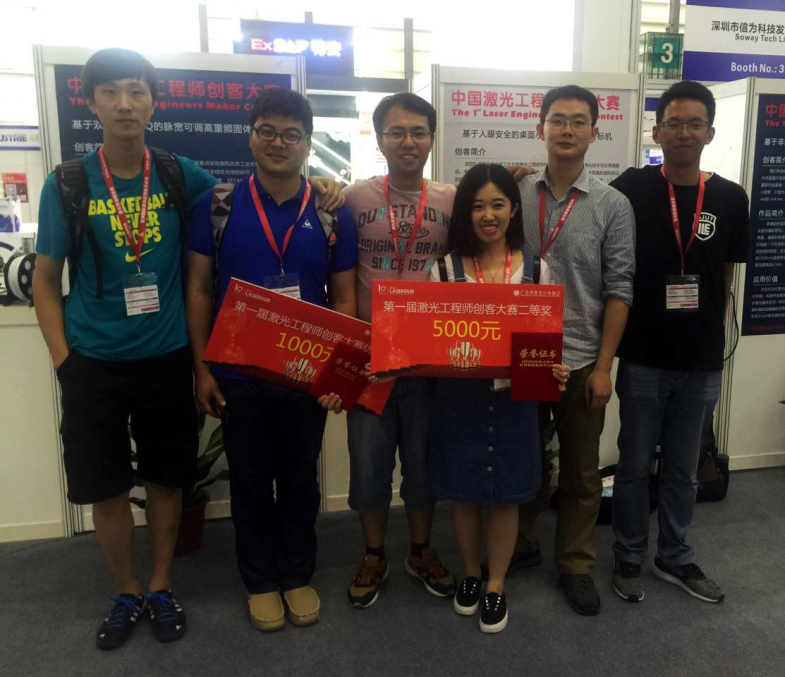

Two maker teams from Institute of Laser Engineering of BJUT participated in “The 1st Chinese Laser Engineer Maker Contest” and achieved good results. The contest was held in the 3rd exhibition hall of Shenzhen Convention and Exhibition Center at 14:00 on May 19, 2016. The contest was backed by “The Tenth Asian (Shenzhen) International Intelligent Manufacturing Exhibition and Forum”. To facilitate the operation of this contest, seven senior experts from Southwest Technical Physics Research Institution, Shenzhen University, and other institutions were invited to be the judges. After rounds of competition, eight teams advanced into the finals. The team from Institute of Laser Engineering of BJUT won the Second Prize by “Human Eye Safety-Based Desktop Miniaturized Fiber Laser Marking Machine”, and the team members are Guo Haodong, Zhou Xinwu, Xu Yan, Qi Shuxian, and doctoral student Hou Yubin. More encouragingly, another team from BJUT won the Excellence Award by “Cylindrical Coordinates Type-Based Fusion Sedimentary 3D Printer”, and Wang Wenchun, Jiang Liaowen , and Wei Xiaobo are team members. The majority from the two teams are the first-year postgraduate students.

The two teams received tremendous support from Employment & Entrepreneur Instruction Center, Innovation and Entrepreneur Institute, as well as Institute of Laser Engineering of BJUT. The teams, with the help of BJUT scientific research platform, combined the innovation and entrepreneurship with scientific research and raised new ideas to fill in the vacancies and make up the deficiencies of market product. The project of “Human Eye Safety-Based Desktop Miniaturized Fiber Laser Marking Machine” combined 1.5μm fiber laser with miniaturized marking system. This wave length was more suitable for non-metal materials, and lowered the cost of the complete machine. Most importantly, the damage threshold of this wave length to human eyes was high, so the marking machine with low power could better protect eyes of operator which was of great importance for industrial production. The project “Cylindrical Coordinates Type-Based Fusion Sedimentary 3D Printer” provided with new solutions according to the demand of 3D printing market, which lowered the cost of using these equipment. Thus, it was quite good for the purpose of primary and secondary education as well as personal use. The two projects were highly praised by those attended experts, and they also won the favor of related enterprises.