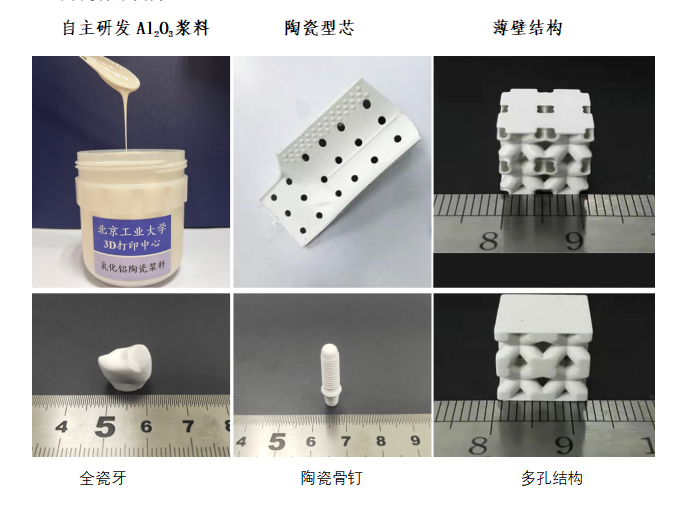

Ceramic cores are critical components in the manufacture of modern aero-engines. 3D ceramic core printing has become the key technology for their production, as their complex shapes are difficult to make using traditional methods. In collaboration with the Kangshuo Group, a team led by Prof. Chen Jimin from the 3D Printing Center, Beijing University of Technology (BJUT) has independently developed large-size 3D ceramic core printers and high-performance ceramic forming materials, solving a major bottleneck problem in China's ceramics 3D printing industry.

The 3D ceramic core printing equipment developed by Prof. Chen Jimin's team can be applied to precision casting, biomedicine and other fields. The equipment, which uses a number of patented technologies with IPR (Intellectual Property Rights), fills gaps in domestic ceramics 3D printing and meets international advanced level requirements. This 3D ceramic core printing equipment has already been put into use for industrial production, providing advanced technical support for the manufacturing of aero-engine ceramic cores.

The main members of Prof. Chen's team include Prof. Chen Jimin, Associate Professor Zeng Yong, and Assistant Researchers Wang Qian and Yao Haihua. Committed to the research and development of 3D printing technology, the team has achieved multiple research successes that are now being applied in the fields of aerospace, biomedicine and other areas. In total, the team has published more than 100 SCI/EI-indexed papers, has applied for over 30 invention patents, and has published 4 monographs.