Energy conservation and carbon reduction are key priorities in the petrochemical industry. Light hydrocarbons, a critical product of naphtha cracking, offer potential for process innovation that can achieve both carbon reduction and efficiency improvement- if, that is, efficient separation of aromatic and aliphatic hydrocarbons can be realized. However, this separation presents a significant challenge.

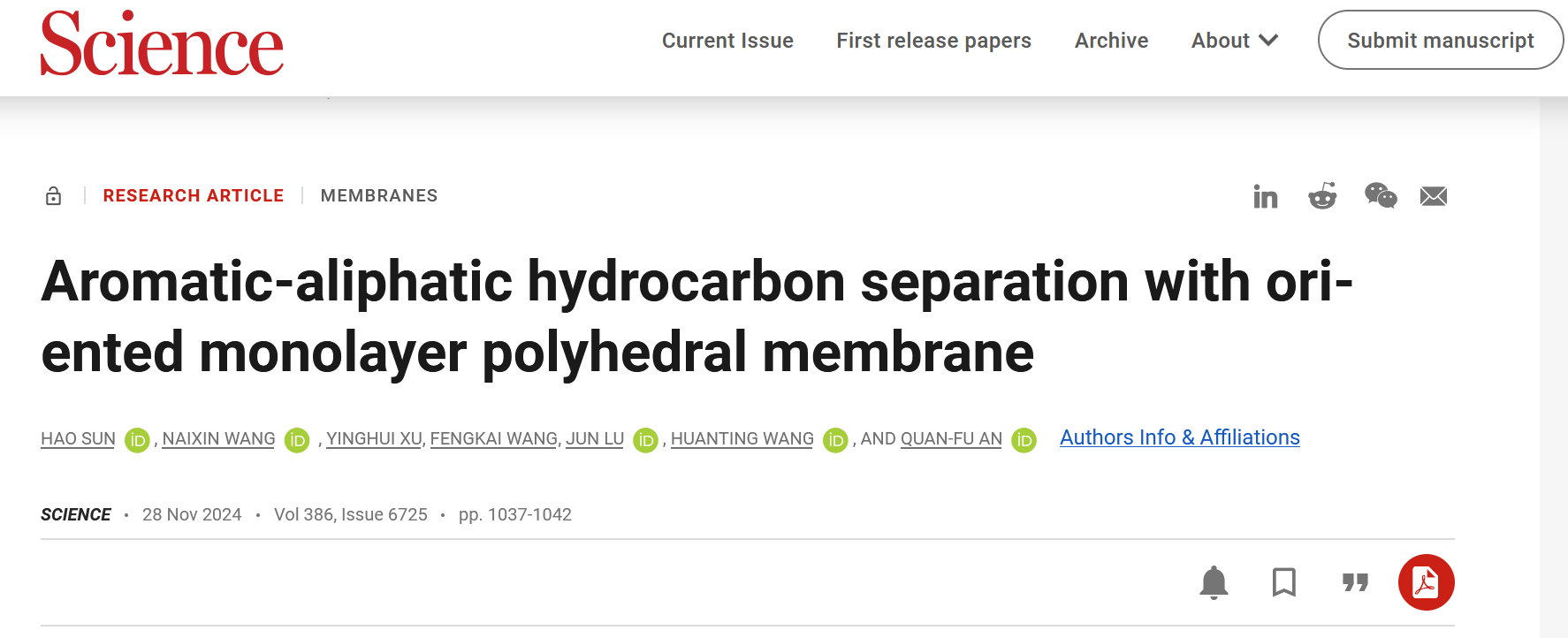

To address this, Prof. An Quan-Fu's team at BJUT's College of Materials Science and Engineering developed a novel membrane fabrication approach with nano-building block. They engineered an oriented monolayer polyhedral (OMP) membrane that consists of a monolayer of ordered polyhedral particles anchored by hyperbranched polymers. This membrane, with a high density of straight, selective nanochannels, enables selective transport of aromatic molecules. By precisely controlling the arrangement and density of the polyhedral particles, the membrane's coverage of the porous support surface reached 85.6%.

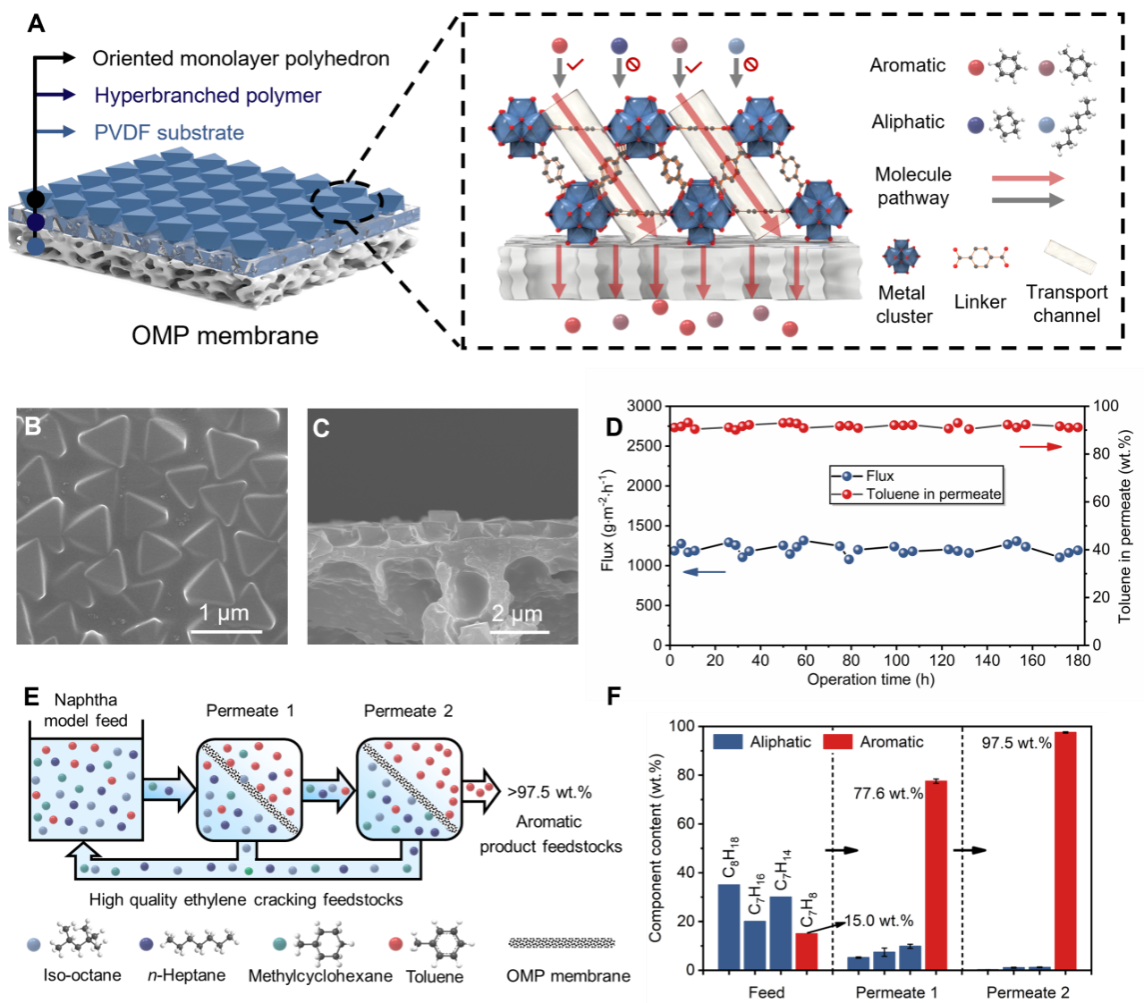

An additional two-stage membrane separation process was designed, which successfully elevated the aromatic hydrocarbon content in the simulated naphtha feed from 15 wt% to 97.5 wt%. This achievement facilitated efficient separation of aromatic and aliphatic hydrocarbons. By utilizing techniques such as low-field nuclear magnetic resonance and molecular simulation, the interactions between aromatic hydrocarbons and the OMP membrane were examined. These investigations provided valuable insights into the preferential adsorption and rapid transfer mechanisms of aromatic molecules within the membrane channels.

This research offers an innovative solution for the efficient separation of aromatic and aliphatic hydrocarbons and offers valuable perspectives for the design of high-performance membranes.

On November 29, the prestigious international journal Science published research by Prof. An Quan-Fu's team from BJUT's College of Materials Science and Engineering, titled "Aromatic-aliphatic Hydrocarbon Separation with Oriented Monolayer Polyhedral Membrane." This study presents an effective solution for separating aromatic-aliphatic hydrocarbon mixtures in naphtha, offering innovative approaches for low-carbon process advancements in the petrochemical industry.

This publication marks another significant achievement for BJUT, with the university once again listed as the first author's institution in Science, highlighting its growing prominence in the field of membrane materials. BJUT PhD student Sun Hao is the first author, with Prof. Wang Naixin and Prof. An Quan-Fu serving as corresponding authors. The co-authors of this paper are PhD students Xu Yinghui and Wang Fengkai from BJUT, as well as Prof. Wang Huanting and Prof. Lu Jun from Monash University, Australia.

(A) OMP membrane structure and transport mechanism of aromatic molecule;

(B and C) Microstructure of the OMP membrane;

(D) Aromatic/aliphatic hydrocarbon separation performance of the OMP membrane;

(E) Two-stage membrane series separation process for naphtha model feed;

(F) Separation performance of the OMP membrane for naphtha model feed

BJUT is one of the earliest institutions in China to engage in membrane separation technology research. Over the years, the university has focused on applying membranes in fields such as energy, health, and environmental protection, conducting research in membrane material development, module preparation, membrane-fouling control, and various other applications.

With the strong support and efforts of multiple generations, BJUT has achieved innovative breakthroughs in areas such as redox flow batteries, carbon dioxide capture, water treatment, and drug separation and purification. These findings have been published in leading international journals, including Science, Nature Nanotechnology, Nature Water, Science Advances, Angewandte Chemie International Edition, Advanced Materials, Journal of Membrane Science, AIChE Journal, and Journal of Materials Chemistry A. Some results have been licensed for industrial use, facilitating large-scale membrane production and advancing their engineering applications.

Link to the original paper:

https://www.science.org/doi/10.1126/science.adq5577