On July 26th, the prestigious international journal Science published a groundbreaking paper by a team led by Professor Wang Jinshu from BJUT's College of Materials Science and Engineering, in collaboration with Professor Chen Kexin from the University of Science and Technology Beijing and Professor Huang Mingxin from the University of Hong Kong. The research, titled "Borrowed dislocations for ductility in ceramics", is the first in the world to demonstrate room-temperature tensile ductility in ceramics, achieving a tensile elongation of up to 39.9% and a strength of approximately 2.3 GPa. This marks the second time BJUT has been the primary contributor for a paper published in Science, signifying a significant advancement in the University's materials research.

Rare earth materials can be added to metals to improve their mechanical performance and functionality, due to their special magnetic, optical, electrical, catalytic, high hardness and corrosion resistance properties. Consequently, rare earth materials are widely used in structural materials, composite materials, thermionic emission materials, semiconductor materials, and magnetic materials. However, when used in ceramics, composite materials with a high content of rare earth oxides can be very brittle, which limits their wider application. Because of this, improving the ductility of rare earth ceramic materials has been one of the most critical challenges in the field of structural and functional materials.

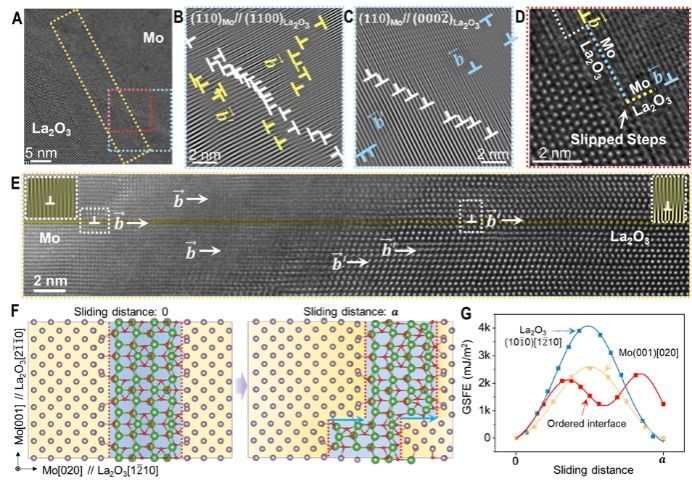

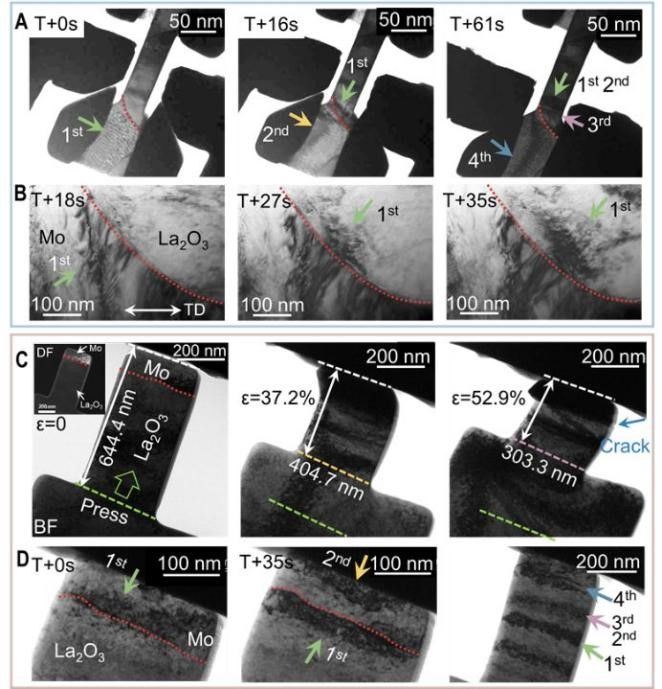

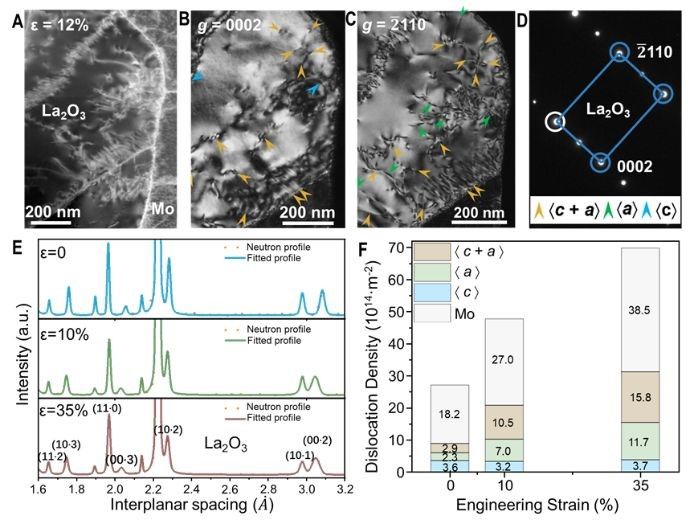

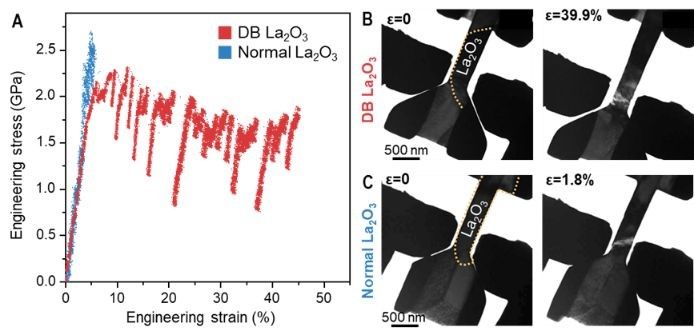

BJUT’s research in rare earths and refractory metals was established by Professor Zhou Meiling and Professor Zuo Tieyong (CAE Member). Under their guidance, Professor Wang Jinshu has been researching rare earth-refractory metal materials since her doctoral studies. Recently, her team discovered that composites with high additions of lanthanum molybdenum oxide still exhibit good tensile ductility. In collaboration with Professor Chen Kexin and Professor Huang Mingxin, Professor Wang pioneered a "borrowed dislocation" strategy: by constructing a tailored interfacial structure with well-ordered bonds between the molybdenum metal and lanthanum oxide ceramic phases (Figure 1). This interfacial structure can significantly reduce the energy barrier required for metal dislocations to transfer into the interior of the ceramic (Figure 2), enabling the ceramic to continuously "borrow" dislocations from the metal (Figure 3), so that a large number of dislocations in the ceramic at room temperature can be achieved. The dislocation density in the ceramic is equivalent to that in the metal after the same deformation (Figure 4), thus achieving the same tensile plasticity of ceramics as in metals. The tensile deformation of ceramics can be as high as 39.9% (Figure 5), which breaks the traditional perception that ceramics cannot have tensile plasticity.

Figure 1: Mo-La2O3 ordered interface structure and first-principles calculation results, proving that the ordered interface is chemically bonded and the crystal plane is continuous.

Figure 2: Dislocations form a slip band after crossing the interfacial structure, and first principles calculations prove that the interfacial structure can reduce the energy barrier for dislocation transmission.

Figure 3: In in-situ tensile and compressive experiments, it can be seen that the molybdenum dislocation clusters continuously transmit into the interior of the lanthanum oxide ceramic through the interfacial structure, allowing the ceramic to stretch and bend.

Figure 4: Dislocations in lanthanum oxide ceramics after "borrowing", and dislocation density in ceramics after different degrees of deformation.

Figure 5: Room temperature tensile curve of lanthanum oxide ceramics.

BJUT is listed as the primary contributor, with the Yongjiang Laboratory in Ningbo, the University of Hong Kong, and the University of Science and Technology Beijing as collaborating institutions. Professor Wang Jinshu from BJUT, Professor Chen Kexin from the University of Science and Technology Beijing, and Professor Huang Mingxin from the University of Hong Kong are the corresponding authors of this paper. Dong Liran, Zhang Jie, and Li Yizhuang are the co-first authors, and Gao Yixuan and Wang Ming are co-authors. This research was a Key Program supported by the National Natural Science Foundation of China.

First Author: Dong Liran

A graduate of BJUT and a postdoctoral researcher at the University of Hong Kong, Dong Liran specializes in refractory metals as functional and structural materials as well as plastic ceramics. To date, she has published over 10 papers in journals such as Science, Powder Technology, Materials Letters, and Journal of the American Ceramic Society, and holds three U.S. patents and over ten Chinese patents.

Corresponding Author: Wang Jinshu

Wang Jinshu is a professor at the College of Materials Science and Engineering, BJUT. Her research focuses on refractory metal materials and materials for energy and environmental management. Her achievements include four U.S. invention patents and over 50 Chinese invention patents. She has published over 400 high-level papers in journals such as Science, Advanced Materials, and Acta Materialia. She has received one Second-Class National Technological Invention Award and eight first-class and second-class awards at the provincial and ministerial level. Some of her research results have already been applied industrially.